Find a Best Rotary Airlock Valve Manufacturers in Ahmedabad

Unique

A rotary airlock valve has a

majority of material getting pockets having driving edges that are smaller than

the trailing edges thereof, ideally having dividers decreasing deep down in

order to characterize a limited pocket opening for coordinating any material

development because of pressurization to a focal point of a release outlet, to

diminish wear and increment seal life.

Portrayal

Specialized FIELD

This innovation identifies

with a rotary airlock valve and all the more especially to a rotary airlock

valve for exchanging a strong material from a high gas weight entrance thereof

to a low gas weight release.

Foundation

Rotary airlock valves are

outstanding for use in the solids dealing with industry. Frequently, a strong

material is transported to or gotten in a vessel utilizing a pressurized gas,

for example, air. The strong material gathers in the vessel which stays under

strain. The common method to expel the strong material is for it to gather in a

release territory or container which prompts a passage of the rotary airlock

valve.

Rotary airlock valve manufacturers in ahmedabad normally includes a lodging containing a round and hollow load

inside which is mounted a pivotally expanding shaft. The pole has a majority of

radially expanding vanes or edge partitions, with material getting pockets

characterized between the vanes. As the pole turns, the external edges of the

vanes seemingly connect with the inward surfaces of the tube shaped chamber

divider. The rotary airlock valve commonly has an upper channel opening for

getting material, which falls into the accepting pockets between the vanes, as

the pole is turned. There is additionally an outlet opening, commonly on the

base thereof, which enables the material to drop out of the material pockets,

as each progressively turns into a release position. Between the delta and

outlet openings, the vanes characterizing the material getting pockets are in

fixing commitment with the chamber dividers, to keep any by-go of pressurized

gas from the gulf opening to the release opening. The rotary airlock valve

therefore keeps an immediate association between the delta side, which might be

under high weight, and the outlet side which might be at a lower or air weight.

Along these lines, the airlock valve empowers exchange of strong material from

the pressurized vessel, to a transport or other vessel at a lower weight, at

weight contrasts potentially on the request of 5 to 50 mbars.

In a few applications, for

example, while drying a strong material, for example, finely isolated natural

materials i.e., wood mash, sugar beet mash or sugar stick mash; steam might be

utilized with the item to be exchanged. For instance, in the fabricate of paper

mash, wood chips are nourished to a container at up to 12 bars weight, the

chips at that point sustained through the airlock valve to a digester. FIGS. 1

an and 1 b are perspectives of such a rotary airlock valve. The rotary isolated

space all things considered is regularly intended to have a rotor having a base

number of extensive material getting pockets, with an expansive fixing surface

in the middle of the pockets, inferable from the high weight differential.

These airlock valves additionally might be given customizable barrel dividers

that can be moved to enhance the seal between the rotor vanes and the chamber

dividers.

Be that as it may, there are

issues with rotary airlock valves in such an application, especially because of

wear. At whatever point solids exchange happens, there is a potential for the

fixing surfaces to wear, bringing about gas by-go around the rotary air valve.

This is an especially significant issue when taking care of mash, as this may

contain sand, which is very grating. Likewise, the rotary airlock valve

regularly incorporates a seal or gasket between the turning vanes and the

static lodging divides, and any solids attack can prompt fast wear that can

result in gas spills outside of the lodging. At the point when such spillage

happens, the framework must be closed down, bringing about exorbitant preparing

delays. Commonly, such rotary airlock valves have an extremely constrained life

in the brutal mash benefit portrayed above, of around two months.

This issue is especially

intense when the rotary airlock valve exchanges a dried strong material from a

weight of around 2.5 bar, to climatic weight, with superheated steam being the

pressurizing gas. As the pole turns to the release opening, the underlying

break to the low weight side causes a solid outpouring of steam, causing the

dried material be quickened as it is driven out of the pocket, at speeds of up

to 300 meters for each second, expanding the grating impact and wear on the

contiguous parts, especially the edge of the opening. Likewise, the glimmering

of the steam from the pocket can cause buildup and wetting of the powder

material or nearby surfaces, that may prompt item aggregation.

With each progressive turn of

the room, the extension impact increments because of a wearing of the fixing

surfaces, in the end bringing about a gas by-go around the valve.

Synopsis OF THE INVENTION

It is a question of the

present creation to furnish a rotary airlock valve with lessened wear

attributes.

It is a further protest of the

present innovation to give a rotary airlock valve that can promptly deal with

steam extension impacts without expanded wear.

These and different objects of

the present creation are accomplished by a rotary airlock valve involving:

a lodging having a bay opening

and an outlet opening;

a rotor arranged in the

lodging and being rotatable in that;

a majority of vanes radially

reaching out from the rotor characterizing a majority of material accepting

pockets there between, each pocket having a forward or driving edge, and a

trailing edge, the forward edge being smaller in width than the trailing edge,

to shape an ostensibly decreasing pocket.

By ostensibly narrowing the

forward edge, and after that growing to a more extensive trailing edge, any

development of gas or molecule increasing speed is coordinated by the

restricted forward edge far from the side edges of the lodging, to lessen the

wear impacts on the lodging dividers and related seals. Once the weight is

drained, the more extensive trailing edge guarantees that all the material in

the pocket is released.

In another exemplification,

the pockets have side dividers merging from an inward end to an external end

thereof, to add decreasing to the whole pocket. In yet another epitome, the

main edges of each pocket are dislodged somewhat with respect to each other,

for instance beginning near a first side of the lodging and moving in amazed

augmentations over the width of the barrel to convey the wear impacts over the

whole width of the chamber, while as yet getting the advantage of the limited

forward edge plan. Along these lines, the life of the rotary valve manufacturers

can be broadened significantly further.

Ideally, numerous little

chambers are characterized by the vanes rather than a couple of expansive

chambers, as this further lessens the amount of caught steam inside any one

pocket. Ideally, in excess of 6 pockets are given, most ideally around 7 to 12

pockets are utilized. The forward edge ideally has a width that is around 50 to

80% of the width of the barrel, the trailing edge having a width of from 75 to

100% of the width of the chamber. Likewise, the decrease point of the side

dividers of the pocket can change and is ideally an edge more prominent than 2

degrees of the hover of the upheaval.

BRIEF DESCRIPTION OF THE

DRAWINGS

FIGS. 1 an and 1 b are

perspectives of an earlier workmanship rotary airlock valve.

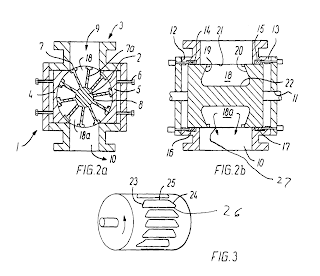

FIG. 2 a will be a perspective

of the rotary sealed area of the present development, FIG. 2 b being a cross-sectional

view brought line B—B thereof

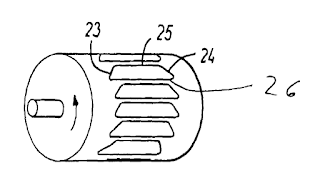

FIG. 3 is a point of view

perspective of a rotor as per the present innovation.

FIGS. 4 A and 4B are elective

epitomes of the present development.

Itemized DESCRIPTION OF THE

INVENTION

Alluding to FIG. 2 an, a

rotary airlock valve 1 has a rotor 2 arranged in a lodging 3 having a couple of

versatile round and hollow fixing dividers 4 and 5. These are balanced by

screws 6 to guarantee a positive seal with vanes 7 that reach out from a center

8 of the rotor. The lodging has a delta opening 9 and an outlet opening 10.

Alluding to FIG. 2 b, the rotor is mounted to a pole 11, driven for revolution

by an engine (not appeared). The lodging has side segments 12 and 13, each

having a perimeter groove 14 and 15 that get a fixing material or gasket 16 and

17 in that. The fixing material might be a gasket, a compressible pressing, or

some other regular seal generally used to seal such turning parts.

In FIG. 2 b, a material

accepting pocket 18 is demonstrated contiguous the bay opening for getting a

strong material in that. The pocket shape is characterized by the contiguous

vanes, 7 and 7 an, and has focalizing side dividers 19 and 20 to such an extent

that the pocket opening 21 is of littler cross-area than a pocket base 22.

Ideally, these are slanted from the smaller forward edge to the more extensive

trailing edge, to give notwithstanding discharging after the weight is eased.

In this encapsulation, upper edges 23 and 24, appeared in FIG. 3, are decreased

deep down, toward a path of turn of the rotor, giving a forward or driving edge

25 having a smaller width than a width of the outlet opening, while the

trailing or rearward edge 26 has a width relating to the width of the outlet

opening.

It is wanted to use a bigger

number of littler pockets, as the lessening in volume per take has a natural

damping impact on the pressurized release talked about above, and no less than

7 stashes, all the more ideally 7 to 12 pockets ought to be utilized.

The forward edge ideally has a

width that is around 50 to 80% of the width of the outlet opening, the trailing

edge having a width of from 70 to 100% of the width of the outlet opening.

A pocket 18 an is demonstrated

nearby the release opening 10. As is shown by the bolts 27, any gas development

or molecule increasing speed is coordinated to the focal point of the opening,

along the main edge 25, bit by bit growing as the rotor keeps on progressing

toward revolution. By breaking generously amidst the outlet opening, rather

than over the whole width on the opening, the underlying extension impact

happens far from the side fixing zones, essentially decreasing the capacity to

cause wear or spillage.

Ideally, the pocket has

correspondingly decreased dividers so a main divider related with the main edge

is littler than a trailing divider related with the trailing edge 26, and in

addition having focalizing side dividers, as these will likewise lead the

material and extending gas to a focal bit of the outlet opening on release,

which additionally helps with anticipating obstructing as the beat of growing

gas is coordinated to the focal point of the outlet. Alternatively

consolidating the pocket outline with an expanded number of littler chambers

additionally hoses the extension impact, limiting wear and along these lines

delaying the periods between upkeep shutdowns.

In another exemplification

appeared in FIG. 4A, the pockets can be stumbled as far as the situation of the

main edge, with respect to each other so the wear isn't focused dependably on a

similar piece of the outlet opening. For instance, a first driving edge 25 an

is arranged towards one side of the outlet opening, a second driving edge 25 b

arranged slightly inboard thereof, a third driving edge arranged halfway in

respect to the outlet opening, and so forth. Along these lines, each pocket has

a somewhat extraordinary wear impact, yet the combined impact is to disperse

the wear over the whole width of the outlet opening, while as yet having the

upside of coordinating the underlying weight beat far from the lodging seals.

Obviously, the request of these can be changed, and they require not continue

in such a stunned game plan, and a more arbitrary dispersion might be ideal.

Further, the widths themselves can differ, from driving edge to driving edge

for a similar reason, to appropriate, and in this manner hose the wear impacts

to build the operational existence of the rotary airlock valve. For instance,

alluding to FIG. 4B, a first driving edge 25 d can have a half width, the

following driving edge being 80%, the following 25 f being 65%, and so forth.

Obviously, the course of action can be controlled by one talented in the

workmanship, and custom fitted to the specific device and material being

released, with the goal that a greater amount of these highlights are utilized

in the more extreme applications and conceivably less in those which are less

serious.

While specific epitomes of

this development have been appeared and depicted, it will be comprehended by

those gifted in the craftsmanship that the innovation isn't restricted thereto

and that numerous progressions and adjustments can be made, and the creation is

expected to incorporate any such changes as will fall inside the soul and

extent of the attached cases.

Comments

Post a Comment