Rotary Valve Manufacturers - Shree Techno Engineers

Rotary Valves are likewise

called rotary feeders, rotary valves, or simply rotary sealed areas. Utilized

as a part of both weight style and vacuum style pneumatic passing on

frameworks, these valves fill in as a "bolt" to forestall air

misfortune while all the while performing imperative material taking care of

capacities. In spite of the fact that straightforward, the Rotary Valve is a

basic segment to the effectiveness of a passing on framework. It's imperative

to recall that not every single rotary valve are essentially Rotary Valves -

yet for all intents and purposes every rotary isolated space are rotary valves.

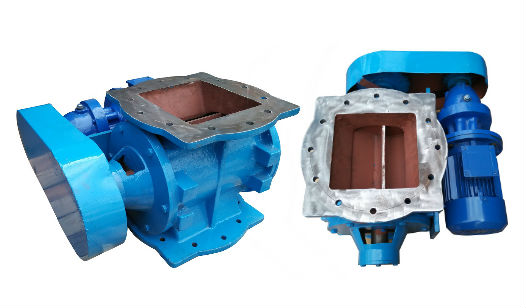

What Happens Inside a Rotary

Valve

The vanes, or metal cutting

edges, of a Rotary Valve turn (pivot) amid activity. As they do, pockets frame

between them. The material being taken care of enters the pockets through the

gulf port before pivoting around inside the valve and after that leaving

through the outlet port. In an isolated space valve, air is fixed (bolted)

between the channel and outlet ports. This enables the materials to movement

descending through the valve from the bay to the outlet port while confining

the wind stream. Material is moved ceaselessly through the nearness of a steady

pneumatic force between the ports. This weight or vacuum contrast must be kept

up inside the valve for appropriate capacity.

A Few Words About the Rotor

Assembly

The rotor gathering in a

Rotary Valve comprises of an arrangement of sharp edges welded to a rotary

shaft. A Rotary Valve Manufacturers is now and again alluded to as a the oar

wheel, impeller, or flipper. A six-vane rotor has six metal sharp edges joined

to the pole, an eight-vane rotor has eight, et cetera. A valve with more vanes

has a tendency to have more noteworthy fixing capacity than one with less. As

the quantity of edges increments, be that as it may, the extent of the pockets

between them diminishes. Bigger pocket measure is perfect for handling bigger

materials or materials that tend to stick or pack together when compacted. Heavier

materials and materials that stream rapidly are not as enormously influenced by

the quantity of vanes and ensuing pocket estimate. It's essential to chat with

an expert to make sense of the ideal setup for the particular materials you'll

be taking care of. Something else to talk about is whether you will require an

open-end or shut end rotor. As a rule, open-finished units are more qualified

for simple streaming non-rough materials and shut finished setups work best for

materials that may have issues with streaming easily.

ReplyDeleteReally good Information thanks for sharing wonderful Blog, keep doing well and keep updating.....

Check valve Manufacturer in Russia & China