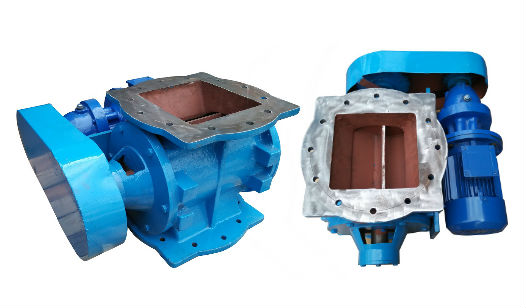

Find a Best Rotary Airlock Valve Manufacturers in Ahmedabad

Unique A rotary airlock valve has a majority of material getting pockets having driving edges that are smaller than the trailing edges thereof, ideally having dividers decreasing deep down in order to characterize a limited pocket opening for coordinating any material development because of pressurization to a focal point of a release outlet, to diminish wear and increment seal life. Portrayal Specialized FIELD This innovation identifies with a rotary airlock valve and all the more especially to a rotary airlock valve for exchanging a strong material from a high gas weight entrance thereof to a low gas weight release. Foundation Rotary airlock valves are outstanding for use in the solids dealing with industry. Frequently, a strong material is transported to or gotten in a vessel utilizing a pressurized gas, for example, air. The strong material gathers in the vessel which stays under strain. The common method to expel the strong material is for it to gather i...